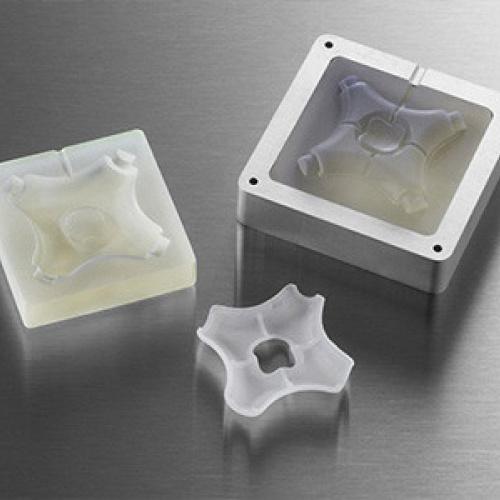

Among one of the most engaging elements of plastic injection molding is its capability to facilitate the makeover of heavy steel parts into light-weight and reliable plastic elements. This transformative procedure not only improves the performance of the end product yet also uses cost-effective advantages as well as opens doors to cutting-edge style opportunities. Allow's explore the benefits that producers gain by accepting this conversion.

China's Proficiency in Plastic Injection Molding: An International Giant

The Introduction of China as a Production Leader

China's ascent to the pinnacle of the manufacturing domain is absolutely nothing short of remarkable. The country's investment in framework, a substantial pool of competent labor, and a favorable service setting have actually paved the way for it to come to be an international giant. The plastic shot molding market has actually considerably added to China's rise as a leading player in the worldwide production landscape. Like To Know About The China Plastic Injection Molding Manufacturer Then See This Web site https://www.djmolding.com/

Among one of the most engaging elements of plastic injection molding is its capability to facilitate the makeover of heavy steel parts into light-weight and reliable plastic elements. This transformative procedure not only improves the performance of the end product yet also uses cost-effective advantages as well as opens doors to cutting-edge style opportunities. Allow's explore the benefits that producers gain by accepting this conversion.

China's Proficiency in Plastic Injection Molding: An International Giant

The Introduction of China as a Production Leader

China's ascent to the pinnacle of the manufacturing domain is absolutely nothing short of remarkable. The country's investment in framework, a substantial pool of competent labor, and a favorable service setting have actually paved the way for it to come to be an international giant. The plastic shot molding market has actually considerably added to China's rise as a leading player in the worldwide production landscape. Like To Know About The China Plastic Injection Molding Manufacturer Then See This Web site https://www.djmolding.com/ For More Information.

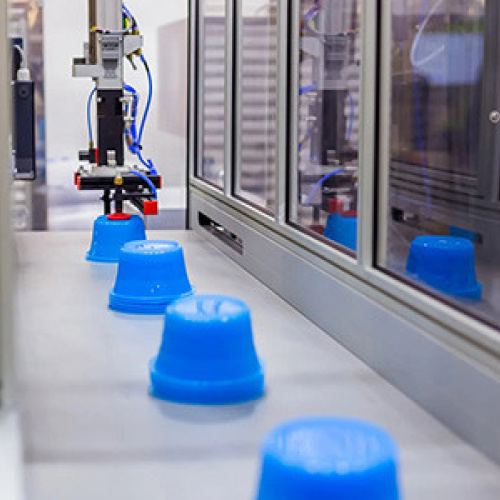

Sophisticated Facilities and Technological Innovations

Chinese plastic shot molding manufacturers have actually not rested on their laurels. To maintain an one-upmanship, they have embraced cutting-edge centers and also the latest technological developments. From state-of-the-art equipment to automation as well as robotics, China's plastic injection molding market is equipped to satisfy the most demanding demands with utmost accuracy and efficiency.

The Peak of Success: Selecting a Reputable China Plastic Injection Molding Manufacturer

Variables to Think About in Choosing a Manufacturer

For More Information.

Sophisticated Facilities and Technological Innovations

Chinese plastic shot molding manufacturers have actually not rested on their laurels. To maintain an one-upmanship, they have embraced cutting-edge centers and also the latest technological developments. From state-of-the-art equipment to automation as well as robotics, China's plastic injection molding market is equipped to satisfy the most demanding demands with utmost accuracy and efficiency.

The Peak of Success: Selecting a Reputable China Plastic Injection Molding Manufacturer

Variables to Think About in Choosing a Manufacturer

The quest for a trusted China Plastic Injection Molding Manufacturer

The quest for a trusted China Plastic Injection Molding Manufacturer needs mindful consideration of essential elements. Companies seeking collaboration must review the supplier's experience, reputation, experience in taking care of intricate projects, quality control actions, as well as adherence to international requirements.

Efficient Interaction as well as Partnership

Successful collaborations are built on reliable communication and seamless cooperation. Overcoming language barriers and also cultural differences is key to developing an efficient working partnership with a China-based supplier. Opting for a manufacturer with multilingual teams as well as a customer-centric approach can cultivate solid connections between parties.

Commitment to Sustainability and also Green Initiatives

As the world embraces sustainability, liable producers are focusing on environment-friendly practices. Lining up with a China-based plastic shot molding maker that accepts lasting techniques not just adds to a cleaner atmosphere however also boosts the company's corporate social duty account.

The Future of Plastic Shot Molding: An Ever-Evolving Perspective

Developments in Product Scientific Research

The future of plastic shot molding is very closely intertwined with advancements in material scientific research. Continuous r & d in polymer modern technology will lead to the discovery of brand-new materials with improved homes, allowing manufacturers to create items with unprecedented efficiency and sturdiness.

Smart Production and Sector 4.0

needs mindful consideration of essential elements. Companies seeking collaboration must review the supplier's experience, reputation, experience in taking care of intricate projects, quality control actions, as well as adherence to international requirements.

Efficient Interaction as well as Partnership

Successful collaborations are built on reliable communication and seamless cooperation. Overcoming language barriers and also cultural differences is key to developing an efficient working partnership with a China-based supplier. Opting for a manufacturer with multilingual teams as well as a customer-centric approach can cultivate solid connections between parties.

Commitment to Sustainability and also Green Initiatives

As the world embraces sustainability, liable producers are focusing on environment-friendly practices. Lining up with a China-based plastic shot molding maker that accepts lasting techniques not just adds to a cleaner atmosphere however also boosts the company's corporate social duty account.

The Future of Plastic Shot Molding: An Ever-Evolving Perspective

Developments in Product Scientific Research

The future of plastic shot molding is very closely intertwined with advancements in material scientific research. Continuous r & d in polymer modern technology will lead to the discovery of brand-new materials with improved homes, allowing manufacturers to create items with unprecedented efficiency and sturdiness.

Smart Production and Sector 4.0

The 4th industrial change, typically referred to as Industry 4.0, is introducing a brand-new period of wise production. With the combination of IoT tools, expert system, and also big data analytics, plastic injection molding is positioned to come to be even more efficient, receptive, and versatile to the developing needs of the market.

Welcoming Circular Economic Situation Principles

As the globe concentrates on lowering waste as well as conserving resources, the plastic injection molding sector is exploring round economy principles. Suppliers are reimagining product life cycles, optimizing product use, and also implementing recycling efforts to reduce the ecological impact of plastic parts.

Verdict:

Plastic injection molding, an ancient yet ever-evolving manufacturing method, remains to shape the globe of item production. China's exceptional climb as a leading plastic injection molding maker has been fueled by its dedication to technology, modern facilities, and also dedication to top quality. Manufacturers worldwide can benefit from partnering with China-based plastic injection molding suppliers, leveraging their knowledge to transform hefty steel components to light-weight plastic elements, enhance expenses, and also bring groundbreaking styles to life.

--

The 4th industrial change, typically referred to as Industry 4.0, is introducing a brand-new period of wise production. With the combination of IoT tools, expert system, and also big data analytics, plastic injection molding is positioned to come to be even more efficient, receptive, and versatile to the developing needs of the market.

Welcoming Circular Economic Situation Principles

As the globe concentrates on lowering waste as well as conserving resources, the plastic injection molding sector is exploring round economy principles. Suppliers are reimagining product life cycles, optimizing product use, and also implementing recycling efforts to reduce the ecological impact of plastic parts.

Verdict:

Plastic injection molding, an ancient yet ever-evolving manufacturing method, remains to shape the globe of item production. China's exceptional climb as a leading plastic injection molding maker has been fueled by its dedication to technology, modern facilities, and also dedication to top quality. Manufacturers worldwide can benefit from partnering with China-based plastic injection molding suppliers, leveraging their knowledge to transform hefty steel components to light-weight plastic elements, enhance expenses, and also bring groundbreaking styles to life.

-- |

Ideas, requests, problems regarding Daya Bay? Send feedback |